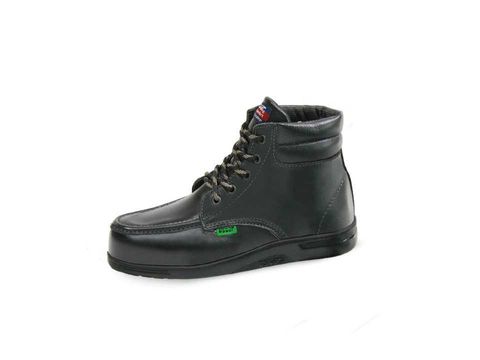

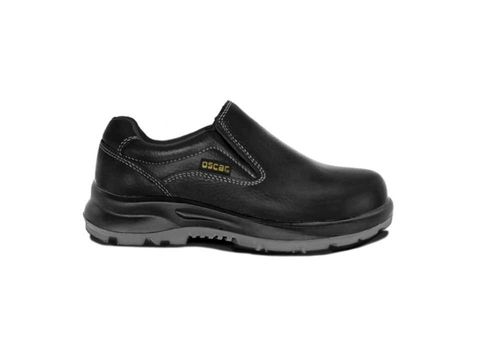

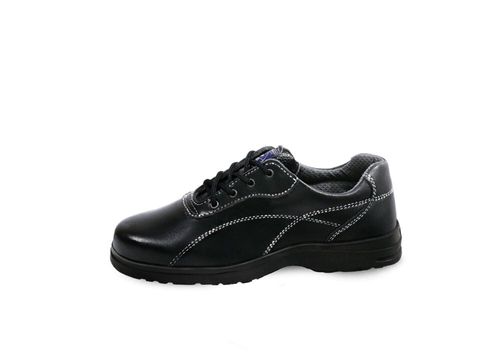

NON ESD

Non-ESD safety shoes are protective footwear designed to prevent electrostatic discharge (ESD) in environments where sensitive electronic equipment or materials are being handled, but in this case, they do not have ESD-specific features like conductive soles.

Features of Non-ESD Safety Shoes:

Durability and Protection: They are typically made with robust materials such as leather, rubber, and composite to protect the wearer from workplace hazards like falling objects, sharp objects, or chemicals.

Slip Resistance: The soles are designed to provide traction and reduce the risk of slipping, especially in wet or oily environments.

Comfort: These shoes often have cushioned insoles, padded collars, and moisture-wicking linings to ensure comfort for long hours of use.

Toe Protection: They often come with steel or composite toe caps for protection against heavy objects dropping onto the feet.

Non-ESD: While these shoes provide physical protection, they don't include features like conductive or dissipative materials in the soles to control electrostatic discharge. They're suitable for workplaces where ESD is not a concern.

Versatility: These safety shoes can be worn in a wide range of industries, such as construction, manufacturing, warehousing, or general industry, where electrical hazards aren't a primary concern.

When to Use Non-ESD Safety Shoes:

In environments like construction, factory floors, or warehouses where physical hazards (such as falling objects or machinery) are present but electrostatic discharge is not a risk.

Suitable for industries such as automotive, logistics, or general manual labor.